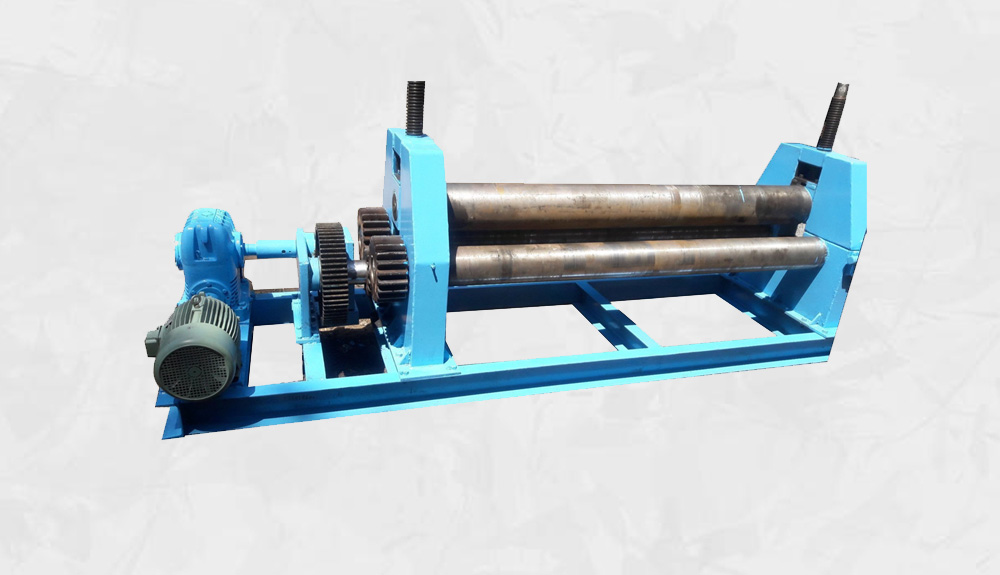

Manual Rolling Machine

A manual rolling machine, also known as a manual roll bender, is a versatile tool used in metalworking to bend and shape metal sheets and plates. Unlike automated systems, a manual rolling machine requires operators to manually adjust the machine settings and apply force to achieve the desired bend or curve. The machine typically consists of three rollers: two lower rollers that are fixed and an upper roller that can be adjusted to control the thickness and curvature of the metal. Operators manually feed the metal through the rollers while adjusting the upper roller to achieve the required shape. Manual rolling machines are valued for their simplicity, cost-effectiveness, and ability to produce custom bends and shapes for smaller production runs or intricate metalwork.